Manufacturing

Digital crossroads in manufacturing: Embrace innovation for efficient & secure supply chains

Manufacturing’s digital evolution: Forging resilient supply chains amidst cyber threats and workforce challenges.

The manufacturing sector is at a significant turning point. Traditional ways of working are changing rapidly due to a combination of low stock levels, a slow uptake of new technology, and an approaching shortage of skilled workers. These factors make supply chains more vulnerable than ever, especially with the constant threat of cyber attacks. Now is the time for the industry to adapt and address these critical challenges.

Overcoming the challenges faced by the manufacturing sector requires a multi-focused approach to technology adoption, workforce optimisation, and enhanced security. Here are some key strategies Airacom delivers to the manufacturing sector worldwide:

Overcome Manufacturing Challenges

Unified Comms

Implement secure and collaborative communication platforms like VoIP and cloud-based voice and video conferencing to connect remote workers, improve collaboration, and address labour shortages.

Cloud services

Migrate to cloud-based solutions for data storage, management, and analytics. This improves scalability, remote access, and disaster recovery capabilities.

AI and IoT

Adopt AI for predictive maintenance, streamlined logistics, and informed decision-making. Employ IoT sensors for meticulous equipment monitoring and production process optimisation.

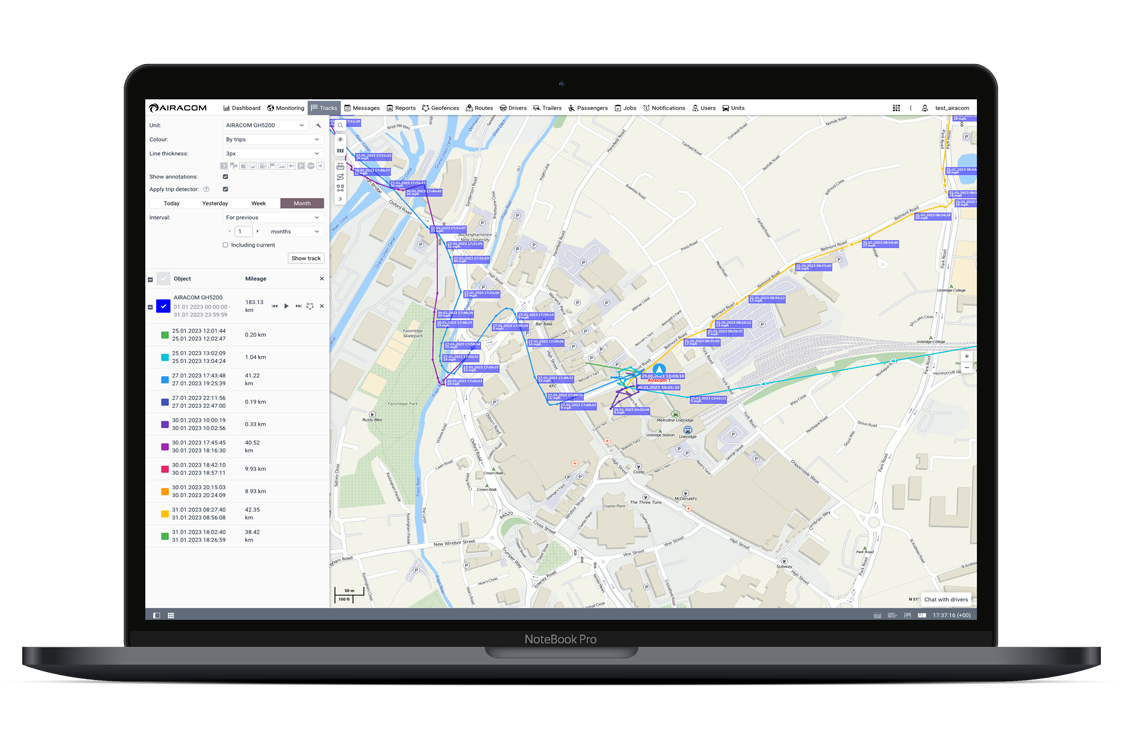

Advanced telematics

Implement sophisticated fleet management systems for accurate real-time tracking, route enhancement, and driver safety, thus improving supply chain transparency and operational efficiency.

Manufacturing Business communications

Combating cyber threats in the manufacturing sector

In the interconnected landscape of modern manufacturing, the reliance on complex system networks substantially heightens susceptibility to cyber threats. The situation in the UK underscores the urgency of this issue:

Recent findings indicate that nearly half, 47% of UK manufacturers have encountered cybercrime within the past year, leading to financial repercussions for over a quarter of 26% of those affected.

The predominant repercussions of such cyber incidents include interruptions to production 65% and damage to business reputation 43%.

Mobile Threat Defence (MTD): Enhances security for manufacturing companies by safeguarding their business-critical mobile devices from risks such as malware and phishing. This proactive defence helps prevent potential financial losses and protects the company’s reputation.

UCaaS: Enhancing your teams collaboration for remote & hybrid work

Adopting advanced technologies is essential for enhancing efficiency and competitiveness in the manufacturing sector. Unified Communications (UC) streamlines collaboration in manufacturing, merging VoIP and video conferencing into one efficient platform.

Through next-generation manufacturing business communications, Airacom empowers manufacturing companies to embrace real-time decision-making and enhance operational agility with Unified Communications (UC). UC boosts productivity by integrating file sharing and task management, enabling manufacturers to swiftly adapt to market shifts and sustain a competitive edge in their manufacturing business communications. This approach ensures manufacturers can respond dynamically to the ever-changing business landscape, leveraging advanced communications technology to streamline processes and improve efficiency.

Benefits of UCaaS for today’s manufacturing companies

Unified Communications as a Service (UCaaS) enhances departmental efficiency and collaboration within manufacturing companies. Here’s how it impacts key departments:

Operations & Production: UCaaS streamlines real-time communication among production teams, minimises downtime, and enhances operational efficiency. It supports immediate data sharing and collaborative problem-solving, which is crucial for meeting production goals.

Supply Chain & Logistics: UCaaS facilitates seamless coordination across the supply chain, from procurement to distribution. It enables effective inventory management and quick response to logistical challenges, ensuring smooth and efficient supply chain operations.

Human Resources & Administration: UCaaS simplifies internal communications, supports flexible working arrangements, and centralises workforce management. It ensures that employees stay informed and aligned with company policies and objectives.

Explore Manufacturing Business Hosted VoIP Systems

PhoneLine+ a Low-Cost Cloud Hosted System

Fiber Broadband: A catalyst for manufacturing breakthroughs

Airacom has been assisting manufacturing companies in improving their production sites, facilities and back office operations with high-speed, secure business broadband. Here are the top three benefits why your manufacturing organisation should switch to Airacom fibre broadband connectivity:

Streamlined Operations: High-speed broadband is pivotal for integrating IoT in manufacturing, allowing real-time equipment monitoring, enhanced efficiency, and reduced downtime.

Data-Driven Decision Making: Fast, reliable internet access enables advanced data analytics and cloud computing, empowering manufacturers with predictive maintenance insights and process optimisation.

Enhanced Collaboration: Robust broadband supports sophisticated communication tools, ensuring seamless collaboration across departments and locations, vital for swift decision-making and maintaining a competitive edge.

Upgrade to Ultrafast Business Fibre Broadband

Is your Company Ready for the PSTN Switch-Off?

Does your Store Need a High-Speed Lease Line?

Manufacturing Business communications

PoC Radios

Manufacturing PoC radios are the walkie talkie alternative offering Manufacturing stores a full group collaboration service over the instore WiFi network.

Manufacturing Workforce management

Driving efficiency, safety, and visibility in your supply chain

In the fast-paced world of manufacturing, staying ahead means leveraging the latest in telematics and vehicle tracking technology. These innovations streamline your logistics and supply chain operations and ensure that every component, from raw materials to finished products, is precisely where it needs to be when it needs to be there.

Enhanced Fleet Efficiency: Telematics provides real-time data on vehicle performance and usage, enabling optimized routing, reduced fuel consumption, and proactive maintenance, keeping your fleet operations lean and cost-effective.

Improved Safety and Compliance: With vehicle tracking, monitor driver behaviour, ensure compliance with regulations, and promote safe driving practices, all contributing to a safer, more responsible manufacturing operation.

Real-time Visibility and Control: Gain unparalleled insight into your supply chain with live tracking of shipments and assets, ensuring timely deliveries, reducing theft or loss, and enhancing customer satisfaction with accurate, up-to-the-minute information.

Precision in print: advanced printing solutions for manufacturers

In manufacturing, the smallest details can have a significant impact. Our extensive selection of high-performance printers, copiers, and Managed Print Services (MPS) is meticulously tailored to address the needs of today’s manufacturers. From enhancing operational efficiency to ensuring strict compliance and safeguarding confidential information, our solutions are designed to streamline every aspect of your printing environment.

Optimised Efficiency and Productivity: Our MPS optimises your print environment, reducing downtime and streamlining workflows with state-of-the-art printers and copiers, ensuring your operations run smoothly and efficiently.

Enhanced Security and Compliance: Secure your sensitive documents and maintain compliance with industry standards. Our advanced print solutions offer robust security features, protecting confidential information from unauthorised access and breaches.

Cost Control and Sustainability: Benefit from a more sustainable print environment with reduced waste and energy consumption. Our MPS provides detailed insights into your print activities, allowing for better cost management and a reduced environmental footprint.

Office Printers and Photocopiers

Ensuring workforce safety and efficiency with innovative people tracking technology

In the dynamic manufacturing environment, your workforce’s safety is paramount. Our Bluetooth Tracking Badge system is a game-changer, offering a sophisticated solution to safeguard and precisely locate workers across your manufacturing sites. This innovative technology not only enhances the security and well-being of your employees but also contributes to operational efficiency and crisis management.

Enhanced Worker Safety: Prioritise your employees’ safety with real-time location tracking, ensuring quick emergency response times and maintaining a secure working environment.

Increased Operational Efficiency: Streamline your operations with the ability to monitor workforce distribution and movement patterns, optimising workflow and resource allocation for peak performance.

Crisis Management and Compliance: Improve crisis response with precise location data and ensure compliance with workplace safety regulations, fostering a culture of trust and security within your manufacturing facilities.

Real-Time Bluetooth location ID Badge

Intrinsic safety unlocked: ATEX-Certified devices for hazardous manufacturing zones

Our ATEX-certified tablets and smartphones are engineered to meet the rigorous demands of hazardous manufacturing. These devices, designed for intrinsic safety, allow seamless and secure communication, data collection, and process management, even in the most harsh, hostile and hazardous zone 1, division 1 production environment.

Chemical Processing: Safely monitor and manage chemical operations in flammable environments with ATEX devices, ensuring process efficiency and safety compliance.

Oil and Gas Operations: In explosive atmospheres of rigs and refineries, rely on ATEX devices for robust communication and data handling, securing operations and emergency responsiveness.

Pharmaceutical Production: ATEX devices support the pharmaceutical sector’s clean and controlled environments by enabling secure data management and process monitoring, ensuring product safety and quality.

Explore Hazardous Area Devices

Zone 1 – Division 1 Smartphones

Manufacturing business communications

Enterprise voice & data services for manufacturing companies

Push to Talk

Replace two way radios with Airacom APTT push to talk offering near national coverage over any IP network.

Workforce Management

Enhance frontline safety with location monitoring, geofence clock, clock out, incident reporting, and job allocation.

Cloud Hosted VoIP

Reliable voice phone systems for your Manufacturing stores and head office collaboration.

Site Connectivity

Get superfast Manufacturing site broadband to run business critical applications and services from Fibre to SD-WAN.

Business Mobile

Improve site productivity with the right mix of rugged devices using a business only 4G and 5G superfast network.

Manufacturing WiFi

Manufacturing site WiFi is packed with features, security and flexibility over a 4G and 5G connectivity with built-in failover.

Manufacturing business communications & data services across the UK and beyond

Explore our comprehensive communication solutions, custom-designed for the Manufacturing industry’s distinctive local and global requirements. Airacom delivers specialised, region-specific support to fuel progress and creativity in the Manufacturing sphere. Dive into our extensive business services, crafted to empower Manufacturing enterprises in your area.

Manufacturing business communications

Mobilise your workforce

Replace two-way radios with Airacom push to talk offering near national coverage over any IP network.

Connect your project site

Utilise IoTs and Sensors to gain real-time data analytics across your sites to make informed business decisions.

Protect your team

Enhance workforce safety with location monitoring to better manage employees operating remotely or alone.